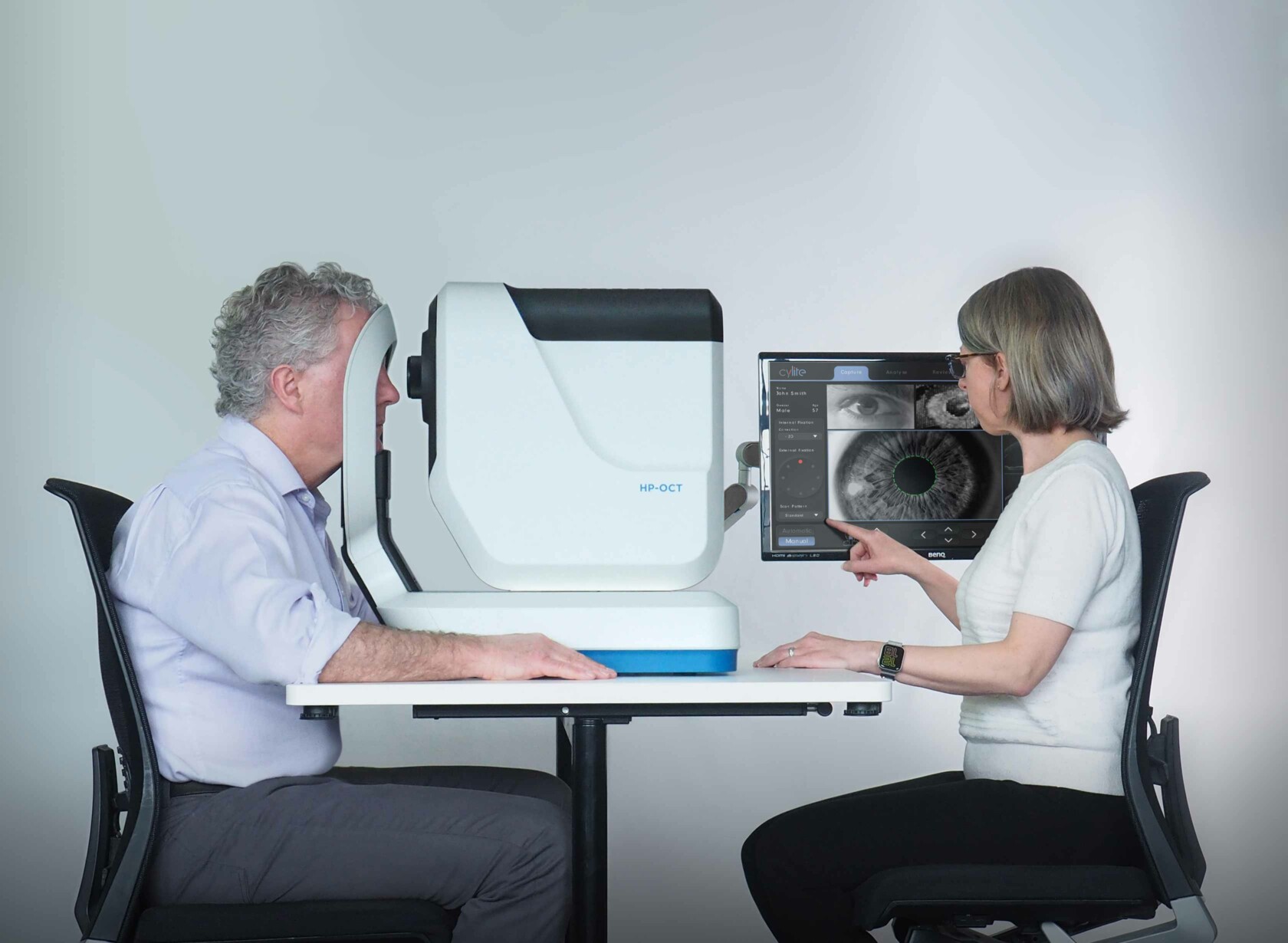

Design for a revolutionary technology

The Cylite HP-OCT is a revolutionary ocular imaging and measurement device that overcomes issues of motion artefacts or data error that result from patient eye movement during traditional imaging procedures. Aimed for use in a variety of clinical settings, including both research laboratories and patient-serving clinics, the HP-OCT has been designed to integrate a high technology core within an ergonomic, user-friendly exterior.

The Team We believe good design happens by expert people working as a team.

Kynan Taylor Project Leader

Jack Magree

Graeme Marshall

Marcus Krigsman

Nat Hunt

Mark Matthews-Frederick

Andrew Fanning

Adam Dean-Smith

Cobalt's brilliant design makes our world-first technology shine on the world stage.

Grant Frisken Cylite Founder and CTO

Other Work

Bio-Rad CFX Opus

The newest real-time qPCR system.

Agilent 4300 Handheld Spectrometer

Laboratory-grade analysis for the outside world through human-centred design.