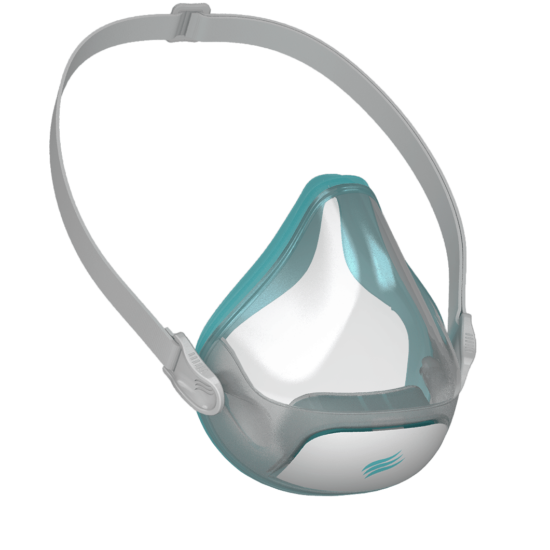

Designed to combat jet lag

The HumidiFlyer mask is a personal travel mask that is designed to reduce dehydration caused by dry cabin air in aircrafts. Dehydration is known to lead to a number of adverse health effects such as jet lag and fatigue.

The HumidiFlyer mask uses a special medical hygroscopic filter to trap moisture from the user’s breath. The trapped moisture then naturally humifies the dry cabin air as it is inhaled – creating a simple, passive circuit to keep travellers hydrated for longer.

Cobalt developed the universal fit mask to ensure high levels of user comfort and convenience. A strong and robust polycarbonate shell is combined with a soft and flexible over-moulded silicone edging that conforms to the user’s face, providing a secure yet comfortable fit. An elegant detachable strap has been designed to allow users to position the strap above or below the ears for comfort and best fit. Care and maintenance are simple – the filter is easily removed from the mask, and both can be washed, keeping the mask fresh for ongoing air travel.

The Team We believe good design happens by expert people working as a team.

Kynan Taylor

Graeme Marshall

Chris Morrish

Andrew Fanning

Other Work

KeepCup Thermal

Double-walled stainless steel reusable cup.

OX Exoskeleton

Passive Defence Force Exoskeleton.