Analysis & Simulation

Our engineers use a variety of market-leading tools and techniques to quantify, optimise and validate solutions throughout the design process.

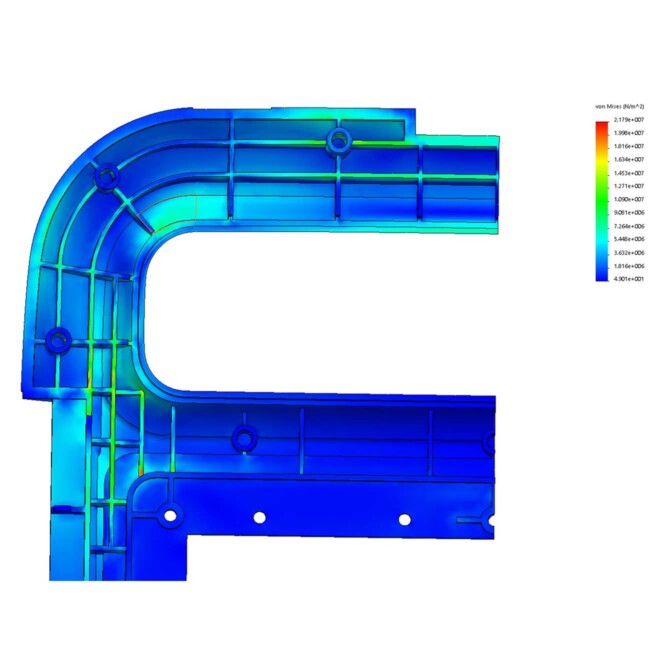

Finite Element Analysis Optimising the solution

Cobalt uses leading computer analysis software to test, evaluate and optimise the performance of components, assemblies, and systems in a virtual environment. This allows us to refine, reiterate and optimise designs and materials before investing in physical prototypes.

Finite element analysis (FEA) is used for analysis of stress, stiffness and safety of mechanical components. Cobalt has experience with static and dynamic load cases including linear and non-linear studies.

Using the latest FEA software allows seamless integration with the engineering design process and 3D CAD environment, further reducing development time and cost.

Thermal Analysis Cool it! Effective thermal management

With electronics embedded within near-impossibly discreet products, thermal management is often a critical factor to achieve performance and reliability. Through a combination of engineering analysis, virtual simulation and physical testing, Cobalt can develop effective solutions to manage and transfer unwanted heat. Solutions can range from passive to active designs, design of heat sinks and thermal transfer mediums, forced cooling and material selection for optimum thermal performance.

Dimensional and Tolerance Analysis Precision defined is precision made

Dimensional and tolerance specification is a critical step in engineering design and quality control. It helps guarantee that parts will be fit for purpose; maximising quality, minimising assembly problems and ensuring reliable product performance. However, specification of overly tight tolerances will lead to increased manufacturing complexity and cost.

Through experience, we take a balanced approach to tolerancing, relaxing the level where safe and practical, while maintaining high levels where necessary to ensure function and quality. This approach requires a solid base knowledge of industry-best standards, and direct, honest discussions with suppliers to achieve real-world production outcomes based on best-practice commercial and manufacturing practices.

Cobalt uses a number of analysis methods to ensure correct dimensions and tolerances are specified. Cobalt’s engineers have extensive experience with tools such as tolerance stack analysis, GD&T, statistical analysis, process capability (Cpk) and compliance specification requirements. Many of these are features incorporated within our CAD platforms, while others require manufacturing knowhow and supplier engagement.