Innovating the everyday

As home to the world’s largest tram network, Melbourne’s DNA and self-identity are deeply entwined with trams. Cobalt has been involved with Melbourne’s trams since the network was privatised in the late 1990s, helping TransdevTSL successfully win the first private franchise, and then working with the subsequent operator, Keolis.

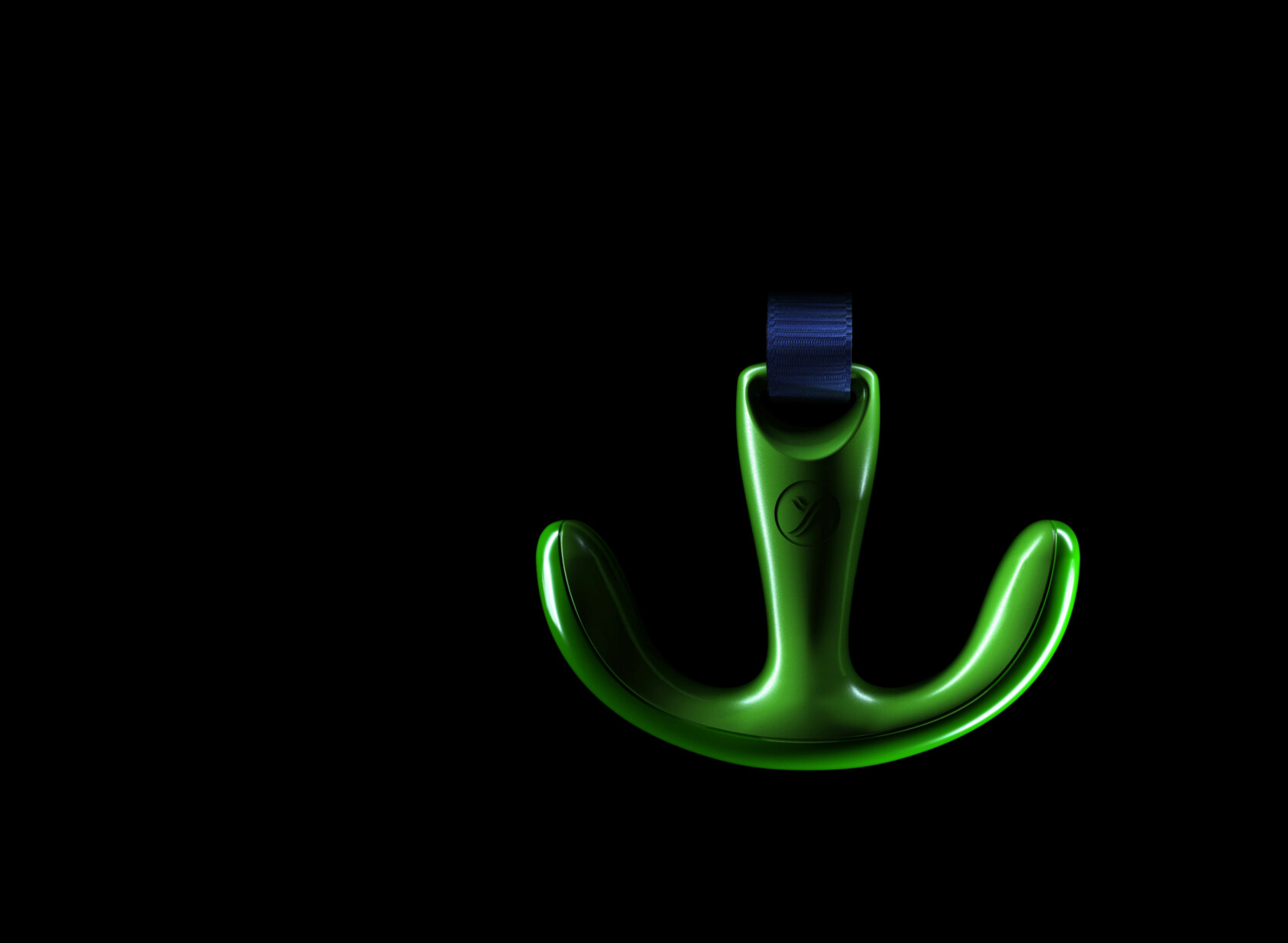

During this time Cobalt provided design and product engineering on a number of refurbishment programs, tech (ticketing, comms) upgrades and amenities development projects. But the most recognisable aspect of our work quickly became an icon of Yarra Trams (and by extension to Melbourne); the Tarzan Passenger Handle.

With the tram network shifting from government-owned to privately operated, Cobalt was given an open brief to look for ways of improving passenger experiences. The Tarzan handle was conceived through user observations of crowded trams and seeing how there was simply not enough hand holds for people to safely ride. This led us to asking ourselves ‘what if we could provide more grab points?’. Once we framed the problem into an opportunity, the concept for Tarzan’s now-iconic anchor shape allowing one or two people to grip, rather than the traditional ‘stirrup’ handle which only one person can hold – evolved almost immediately.

The Team We believe good design happens by expert people working as a team.

Steve Martinuzzo

Jack Magree

Simon Andersen

Within a day of seeing our sketch, Yarra Tram’s said they wanted it. Within 3 months we’d engineered, tooled and were supplying handles for installation across their fleet.

Steve Martinuzzo Cobalt Design Principal

Other Work

KeepCup Thermal

Double-walled stainless steel reusable cup.

Dermapen 4

Dermatology for the digital age.